Điện cực nối đất tải nhanh ZGDK-12

Mã sản phẩm :

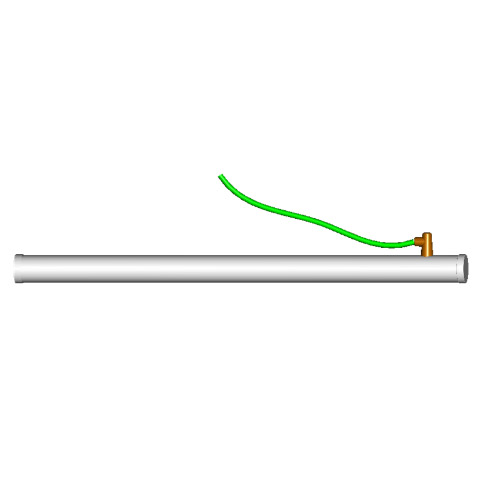

Điện cực nối đất tải nhanh ZGDK-12 là một loại thân nối đất bằng thép được lắp đặt theo chiều dọc. Các lớp phủ đồng, niken và crom trên bề mặt không chỉ tăng cường khả năng chống ăn mòn mà còn mang lại lợi thế về độ dẫn cao, lắp đặt thuận tiện và hiệu suất siêu điện, có thể được sử dụng làm tiếp đất chống sét, tiếp đất bảo vệ tĩnh, tiếp đất làm việc, và tiếp đất bảo vệ. Thân nối đất áp dụng cho thảm đất xây dựng thành phố, hoặc các công cụ và trang thiết bị phải được nối đất trong nhà, nơi thảm đất không thể được thiết kế; Trong khi đó, nó phù hợp với đất sét, đất cát, v.v ... Nói một cách dễ hiểu, nó được tích hợp với sự đơn giản, nhanh chóng, kinh tế và thực tế.

Thông số kỹ thuật

|

Model |

ZGDK-12 |

|

Kích thước tổng thể |

(Φ28x1288)mm |

|

Trọng lượng |

(3.2±0.1)kg |

Cấu hình

Kích thước tổng thể: 28mm × 1288mm

Tiêu chuẩn tuân thủ: Thân nối đất Q / 75875187-9 • 6-2011

Lắp đặt, sử dụng và bảo trì

1 Trong quá trình thi công, kết nối điện cực nối đất với ống nối, sau đó vặn vào đầu hình nón và chốt búa phải có tiếp xúc chắc chắn với điện cực nối đất. Sau đó, nối đầu búa với búa điện và chốt búa với nhau. Khởi động búa điện và đẩy mạnh nó để đập điện cực nối đất xuống đất. Khi các yêu cầu được đáp ứng, vặn vào và siết chặt đầu nối, bơm một ít nước vào khe hở ngoại vi xung quanh điện cực nối đất, rồi dẫn dây đất ra.

2 Trong quá trình thi công, nếu không có búa điện công suất cao, có thể sử dụng búa sắt để đóng điện cực nối đất xuống đất.

3 Khoảng cách giữa nhiều điện cực nối đất dọc phải lớn hơn tổng chiều dài của hai điện cực lân cận. Dây dẫn đồng bị mắc kẹt (BVR-25mm2) có thể được sử dụng để kết nối hoặc hàn hai điện cực nối đất khác nhau, bằng xử lý khử trùng.

4 Đối với sàn xi măng, gạch hoặc đá granit, trước tiên bạn có thể sử dụng búa điện với chiều dài 400mmΦ30 để khoan đất cho đến lớp đất, sau đó đóng điện cực nối đất xuống đất.

5 Nếu đá cứng hoặc khối xi măng ngăn bạn tiến xa hơn, hãy sử dụng dụng cụ cắt hàn để cắt điện cực nối đất (cách mặt đất 5cm), sau đó hàn trên đầu nối, bằng xử lý khử trùng sau khi hàn.

6 Nếu chất lượng đất tốt, một số điện cực nối đất có thể được đóng xuống đất với độ sâu lớn hơn 2,4m.

7 Chú ý để ngăn chặn việc nới lỏng thiết bị đầu cuối kết nối và tránh ăn mòn do vật liệu ăn mòn và nước.

8 Tuổi thọ sử dụng có thể đạt 20 năm trở lên.

9 Sơ đồ xây dựng như trong hình bên dưới.

.png)

.png)