ZGDG-11 High Efficient Ion Grounding Electrode

Product code : 1490068277

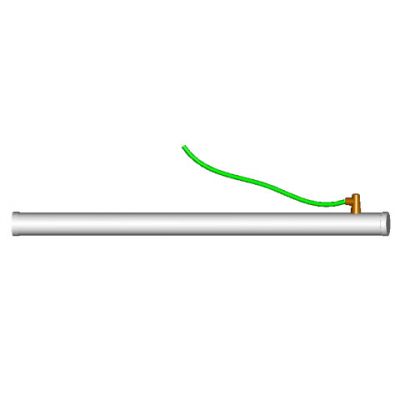

Putting the Φ60 cold drawing steel tube to use, the ZGDG-11 High Efficient Ion Grounding Electrode, with its surface coated with copper, nickel, and chromium, contains the specially-made electrolytic ion compound. It is suitable for various places that have higher demands for grounding, e.g., the lightning protection grounding of buildings (structures), static protective grounding, AC working earthing, DC working earthing, protective earthing and grounding bodies for other purposes

Features The surface of the high efficient ion grounding electrode is made from copper, nickel, and chromium, ensuring high conductivity and corrosion resistance and promoting longevity. With the specially-made electrolytic ion compound and highly polymerized hygroscopic material, the active ions infiltrate into the surrounding soil after absorbing and deliquescing, to improve the current-scattering condition and reduce grounding resistance. Especially in the places with high soil resistivity, with the specially-made backfill materials for ZGJZ1, the lightning impulse current and fault current can be scattered more rapidly. Technical Parameters

.jpg)

Configuration

Overall dimensions: 1115mm×160mm×70mm

.jpg)

- Standards Complied Q/75875187-9·6-2011 Grounding Body Installation, Usage And Maintenance

Installation

1 According to local conditions, the round or radial arrangement is adopted ordinarily for the electrode arrangement, with the distance among grounding electrodes not shorter than 2 times the length of the grounding electrode itself.

2 The grounding electrodes can be buried with the hole-drilling method or buried vertically in the pit. The diameter of hole is 15cm, and its depth should be greater than the length of grounding electrode for 50cm. The connecting terminals should be basically in line with the horizontal slot, as indicated in Fig. 2.

3 When the pit is ready, unscrew the screws of liquid inlet hole and infiltration hole (no marks) of the grounding electrodes (except for fixed screws with the red mark), and place the electrodes in the preset position.

4 Remove the tube cap, inject 500ml of water into the tube, and tighten the cap.

5 In the areas with high soil resistivity, backfill the prepared ZGJZ1 high effective resistance-reducing agent (Note: The ZGJZ1 high effective resistance-reducing agent is a non-toxic dry power compound) to the surroundings of grounding electrode carefully to the full. You can add 80% of water to the resistance-reducing agent, to make it semi-liquid and pour it around the electrodes. Backfill the soil between the top of grounding electrodes and ground surface, and sprinkle some water for compaction.

6 The welding or crimping (when the welding cannot be applied) can be used for connection of multiple grounding electrodes. Dig a horizontal slot with the width of 30cm and depth of 60cm, as indicated in Fig. 3. The 40mm×4mm zinc-coated steel can be utilized for horizontal welded connection, which should be reliable and in accordance with specifications. After the welding, clear the welding slag, and apply a layer of pitch or anticorrosive paint. At last, backfill some soil for compaction.

7 Measure the work frequency grounding resistance after the burying work.

.jpg)

.png)