APPLICATIONS OF HOT DIP GALVANIZING TECHNOLOGY IN MECHANICAL PRODUCTS

Please read part 1 again if you have not read:

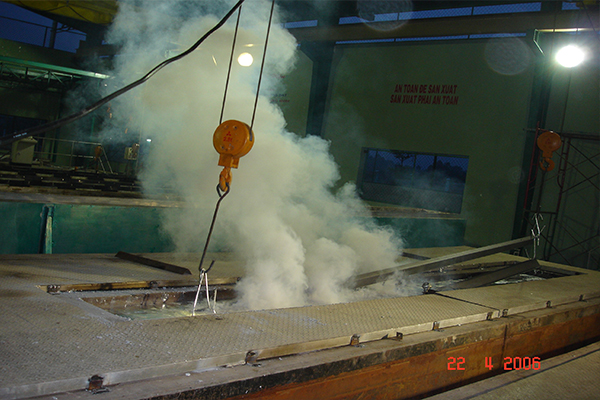

Learning about hot dip galvanizing technology in mechanical products

Applications of hot dip galvanizing technology:

Technology of dipping hot zinc to prevent metal corrosion for steel structures is applied quite popular in developed industrialized countries, but in Vietnam, it’s only started to research and deploy with production scale since 1989 and was strongly promoted when building the North-South 500kV transmission line for industrialization and modernization of the country.

Corresponding materials and zinc dipping technology have been deployed in time, meeting the requirements of corrosion resistance, improving the quality and longevity as well as the safety of steel structure works and have been awarded. 3 VIFOTEC in early 1995.

Objects applied mainly are construction works with large steel structures such as oil rigs, bridge girders, steel beam girders, high steel column structures, chain hydroelectric dams, sluice gates, ship hulls, etc. Specifically:

Telecommunications: the system of products in the post - telecommunications - television industry such as BTS, antenna poles, antenna posts, etc.

Electricity industry: Electric poles

Currently, the products of hot dip galvanizing in Vietnam are mainly electric transmission line accessories made of steel, television towers, soft railings to protect roads, urban lighting poles.

Galvanizing has proven superior protection for buildings, so almost all of buildings of the electrical industry today use hot-dipped galvanized iron and steel.

Longevity of plating layer:

The expected Longevity is defined as the life until 5% of the surface shows rust. The fact of usage many years ago in some countries shows that with a thickness of 100 - 150µm in general, the spray coating layer for a lifespan of 15-20 years, if there is a support coating usually reaches 25 - 30 years.

Main advantages of technology:

The technology is simple and easy to apply, does not require complex equipment.

This technology can be applied to zinc coating on steel parts with different shapes such as steel bars (rods), steel pipes (straight or curved pipes embedded both inside and outside), steel wires and other types of welded structure etc.

The capacity of galvanizing is hundreds of times higher than that of electrolytic plating.

The chemicals, supplies and equipment of the production line can be purchased domestically.

Other news

- Tìm hiểu về cấu tạo sợi cáp quang và phân loại cáp

- Extreme Announces First Integrated Solution Following Avaya Acquisition

- The design and the applications of twisted –pair cables

- Tìm hiểu về bảng đồng tiếp địa chống sét

- Characteristics and the usage of resin cable ties in the telecommunications industry

- Types of Fiber Optic Patch Cord

- Khuyến Nghị Sử Dụng Máy Đo Ethernet – EXFO ETS-1000 / ETS-1000L

- Khuyến Nghị Sử Dụng Máy Đo Phân Tích Phổ - Anritsu MS2711E

- The differences between Optical Fibers and Coaxial Cables

- Electric Cables – Square Power Cables - Kingsignal | T.A.T Telecommunications

.png)